You might have been wondering if I do anything other than talking about all kinds of philosophical and intense shit these days, which… fair. The good news is that I do, in fact, still build stuff. Like these, for example:

So, here’s a weird thing. During the week most of my daylight hours are not spent spend tearing things apart in my house (and not putting them back together in a timely fashion), or chasing donkeys around my property, or riding around on my tractor, or, you know, hugging chickens…

Nope. Most of my time is actually spent working in an office.

Totally fair if you have a hard time picturing that but I should clarify this by saying, I work in an awesome office (hardly anyone even blinks if I show up a little muddy or with feathers in my hair after morning farm chores), and I work with amazing, talented, hilarious people. For example, in the course of two days, I’m walking up and down the stairwell (that is under construction and therefore labeled for painters) and this unfolds…

Just…

I fucking love these people.

Also, this…

(I took a picture of this because not only do I work with a bunch of smart-asses who know big-words, but it pretty accurately describes how I feel every morning after leg-day.)

I’m lucky because my job involves knowing and working with pretty much everyone in our company so that things run smoothly every day, but, honestly, what that means for me on a day-to-day basis is a lot of email and meetings and spreadsheets and, um, basically nothing to do with power tools. That is, until a couple of months ago, when I built this table…

That had nothing to do with work, except at the time we were renovating our “cafe” space in the office and didn’t have budget for furniture, so they were like, “Hey, that big table you built? Can we build some for the office?”

Oh, you mean spend a few days away from my spreadsheets, playing with power tools up on the farm with my awesome co-workers?

Sigh. Okay, fine. Twist my arm.

I work with so many creative people that have a way better aesthetic than I do, so instead of just re-building the large table I built for my pergola, I immediately recruited some help to design fun tables that would fit in with the look of our new office space.

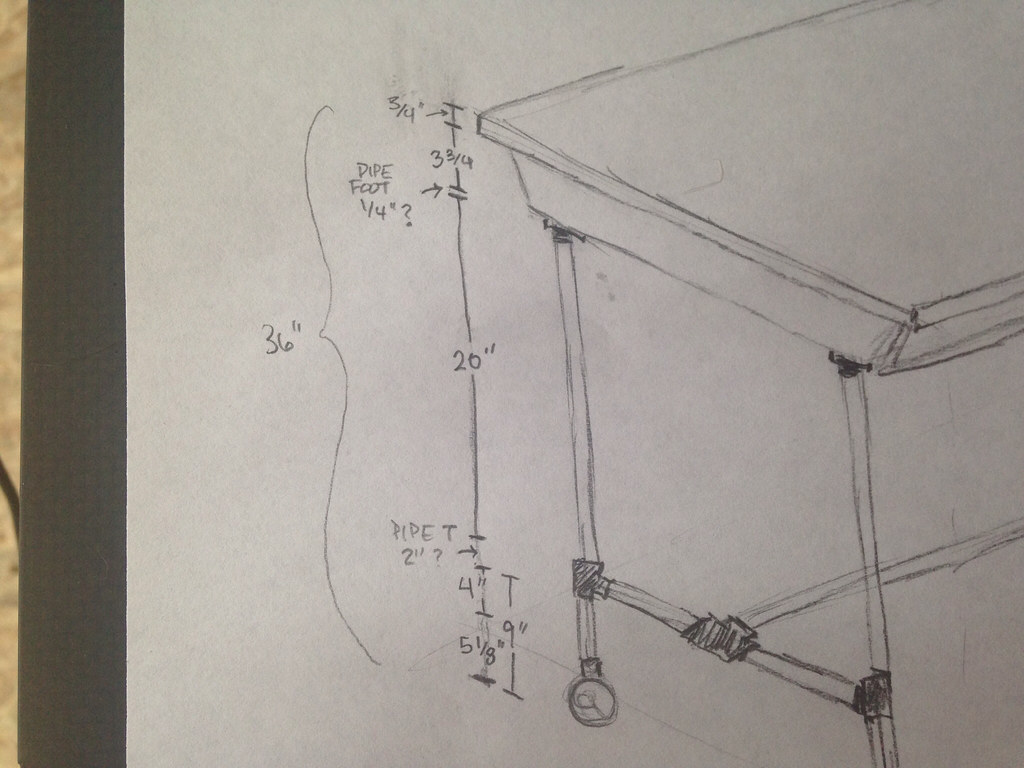

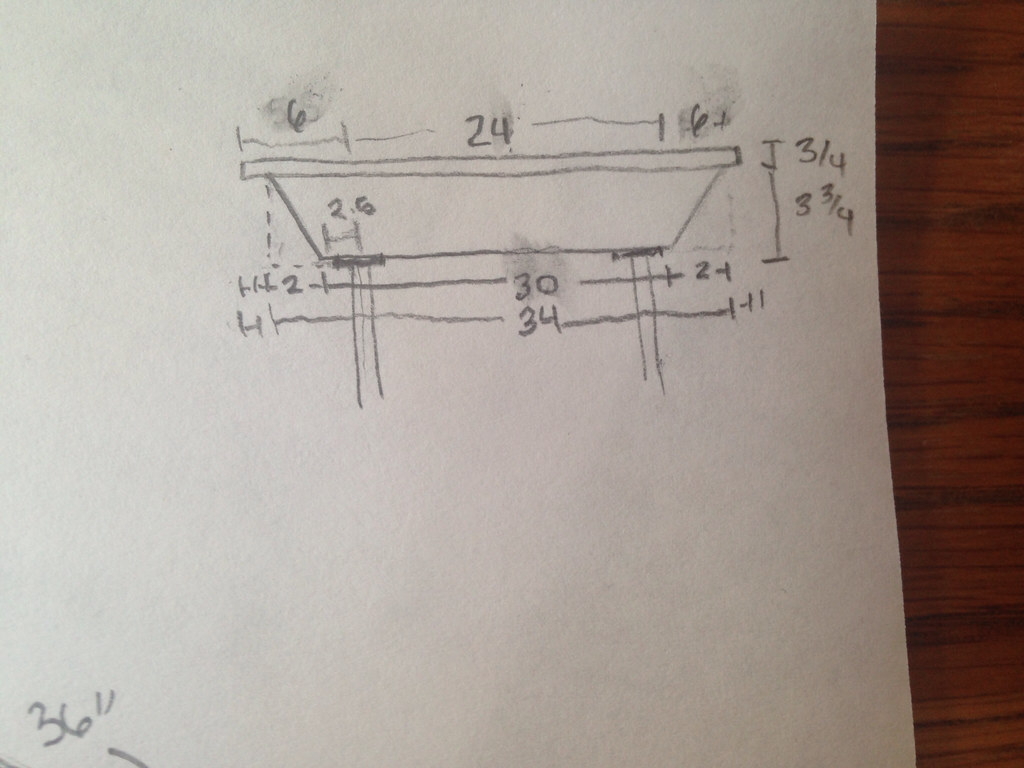

The concept we landed on was meant to be cheap, simple, fun, and reminiscent of those old school-desks we all sat at as kids..

We built 4 tables with these dimensions. They’re counter-height (about 36″ from the ground to the top of the table) and the tops are 36×96″.

The bottom of the table is all gas pipe, and the tops were made strictly from 3/4″ cabinet-grade birch.

Most of the time I build things alone… it’s how I work best. So I wasn’t sure how building four tables as a team would go, but I figured it’s Friday, we’re on the farm, there’s beer, and only one of us almost lost two fingers to a table-saw once (wasn’t me), I’m sure it’ll be fine.

Okay, so I introduced everyone to my, “eh, let’s just roughly assemble one, see what we think, and adjust the measurements as we go” style of building.

Which, in retrospect, may not be the best method when you’re cutting four tables-worth of pieces. (Let’s just stay there was some re-cutting that had to happen a few days later for a couple of pieces.)

If I had to do this again I would have fully built one of the tables first (with a smaller number of people) then taken that apart and used the pieces as guides for a larger group to build the other 3 tables.

Still, for having 8-10 people we broke into groups and managed to get a lot of work done quickly. Like you see here…

Where the girl is doing all the cutting and the guys are just standing around…

Ha. Just kidding guys. That was actually a test cut before we really got started, but once we did we had 3 different cutting stations. 1.) Trimming the top boards down, 2.) cutting the sides and middles, and 3.) running the bottom boards through the table-saw to get the angle on them (which was a 3-man job, minimum. I really need that panel saw…)

The chickens also helped, obv. The chickens always help.

We also had people spray-painting and assembling the gas-pipe legs…

(Those are upside-down, just for reference… if you’re trying to figure out how we built these.)

And then as we progressed, we had a team that was sanding the pieces and ironing veneer on to the edges of the plywood for the tops.

Literally the only time I’ve turned that iron on in the last 4 years. Who knew they could be so handy in the shop?

Also, side note: this is the first time I’ve used plywood as a table-top. I usually plank solid boards for something like this because I like the look, but we wanted flat, solid surfaces that we could work on. Adding the veneer strip to the plywood was a game-changer in giving the tops a finished look.

Once everything was sanded, people got to work painting. (And yes, the wood-hauling trailer will double as a panting surface when needed… having a huge barn to paint in didn’t hurt either.)

And some people took conference calls between painting sessions. The donkeys joined, obv…

It took us about one-and-a-half working days to get here. All the pieces were cut, most of them had one coat of paint, it seemed like we’d have finished tables soon…

The thing we (uh, I) didn’t account for was how damn long it would take to fully paint, stain, and polyurethane all the wood, because (ha) I never bother to really finish my own projects. By that I mean, I don’t always put the last coat of paint or stain on because I’m bored with painting and just want to see the thing assembled. Which is no big deal at my house, but with work tables they need to both look good and be durable.

This was the first “assembled” table in my garage without any poly.

It was clear at this point we were going to get caught in an endless cycle of touch-ups and 3rd coats of paint, and we couldn’t afford any more time away from the office, so, instead, we brought the work to, well, work. We dis-assembled everything, packed it in my truck so it wouldn’t get scratched/damaged on a hour drive (even with my shitty driving) then spread everything out in our cafe area on some tarps and stain/paint/poly all of the pieces for the third or fourth time between our other meetings…

And also sometimes on nights and weekends…

I’m telling you, legitimately finishing the tables–which meant 3 coats of paint on the interiors, 2 coats of ebony stain on the tops, two coats of white-wash on the sides, and then 3 coats of poly on both the tops and sides–took twice as long as actually building them did.

I don’t have the patience to build and finish furniture like this all of the time, but for what is basically a couple of sheets of plywood, they ended up looking quite polished in the end.

Here’s the transformation with stain..

(Then, after wiping off the excess and letting it dry, a second coat.)

Then the poly, sanding it down with 400-grit between coats.

This is what it looks like with the poly wet…

Here’s the finish, dry:

I used Fabulon’s Satin poly, which I also use on my floors, and on this TV console table. It’s the best finish I’ve ever found in a poly (Minwax’s satin is far too shiny for my tastes.)

Actual assembly of the tables mostly used pocket screws. I used 1-1/4″ screws on all of the “inner” pieces– attaching them directly to the top.

Then we put the bottom board on and screwed up through the bottom of the board into the inner pieces. This left no visible fasteners (and we just caulked the pockets on the the interior and painted over them.)

The legs are attached with screws through the pipe flanges, and the wheels are expanding-stem casters that fit right up inside the 3/4″ pipes (they have a rubber stem, and you just tighten the nut on the stem until the rubber expands enough to make a tight fit in the pipe.) I got the ones we used here.

All in all, I think they turned out pretty awesome…

Not just because they were pretty cheap for 3×8 tables (only about $250-275 apiece) but because we designed and built them together so that we all have a place to sit, eat, work, and hang-out with each other in our office…

As far as adding unplanned projects to my list of things to build this year, this one was pretty awesome.

No comments:

Post a Comment